Confidently plan your warehouse relocation with our Warehouse Relocation Playbook

The playbook created by a Logistics Operations Expert provides you with a checklist for planning your warehouse move in detail.

Keeping the business running.

Doors open.

Orders flowing.

ALL THE TIME.

That’s what you want to accomplish as part of a warehouse relocation.

The challenge:

Making sure you achieve this target requires detailed planning and good preparation.

Whether it is about equipment, resources, products, IT systems or the new facility – you need to plan out the steps for each of these areas in detail and make them fit like a puzzle. Only when all the pieces fit together are you able to achieve a smooth transition.

What does good preparation in the context of a warehouse transition look like?

As with any project you’ll have to deal with uncertainties and things that are not under your control (take weather). What you want to accomplish with the warehouse relocation planning is defining the parameters you can control and thus establish constants to base your plan upon.

The activities for a business-critical project such as a warehouse move need to be in good hands. You need dedicated resources which are committed to the mission and who have some “skin in the game”. Your resources play an important role in getting the transition done in a smooth way, especially in peak periods such as the actual move or the cleaning out the old warehouse where you need a lot of helping hands.

Sure enough, your resources also have a day job and they will have to focus on other commitments, but at least make sure you make good estimates for the labor intensive activities and get those resource commitments from the department heads.

Before the actual move, get rid of any dead, obsolete or canceled items. This will not only free up space in the old warehouse which simplifies the move out. It will also reduce the time and effort (and cost) for the transfer to the new facility.

After the decision of warehouse relocation is made, make sure there’s a kick-off meeting with all relevant people involved, from both sides (Company & 3PL Warehouse). (How to run a project kickoff meeting).

Apart from the Project Team, it is mandatory that the Company’s Country Head/Country Manager/Managing Director/Head of Operations/CEO is part of this first meeting so everyone understands how critical this relocation project is for the Company and, most importantly, that he/she will be following the project closely to make sure it accomplishes all timelines/targets.

There are many variables to take into consideration when it comes to the physical transfer of goods from one warehouse to the other:

Leading a warehouse move is a challenging mission, especially when you have never done any project like this before.

There are just so many steps involved and so many pieces to coordinate.

And if any important step was missed during the preparation, you can be sure it’s going to break your schedule and you (and your company) will have to make some tough decisions.

We want to spare you the pain of getting through a poorly-planned warehouse move.

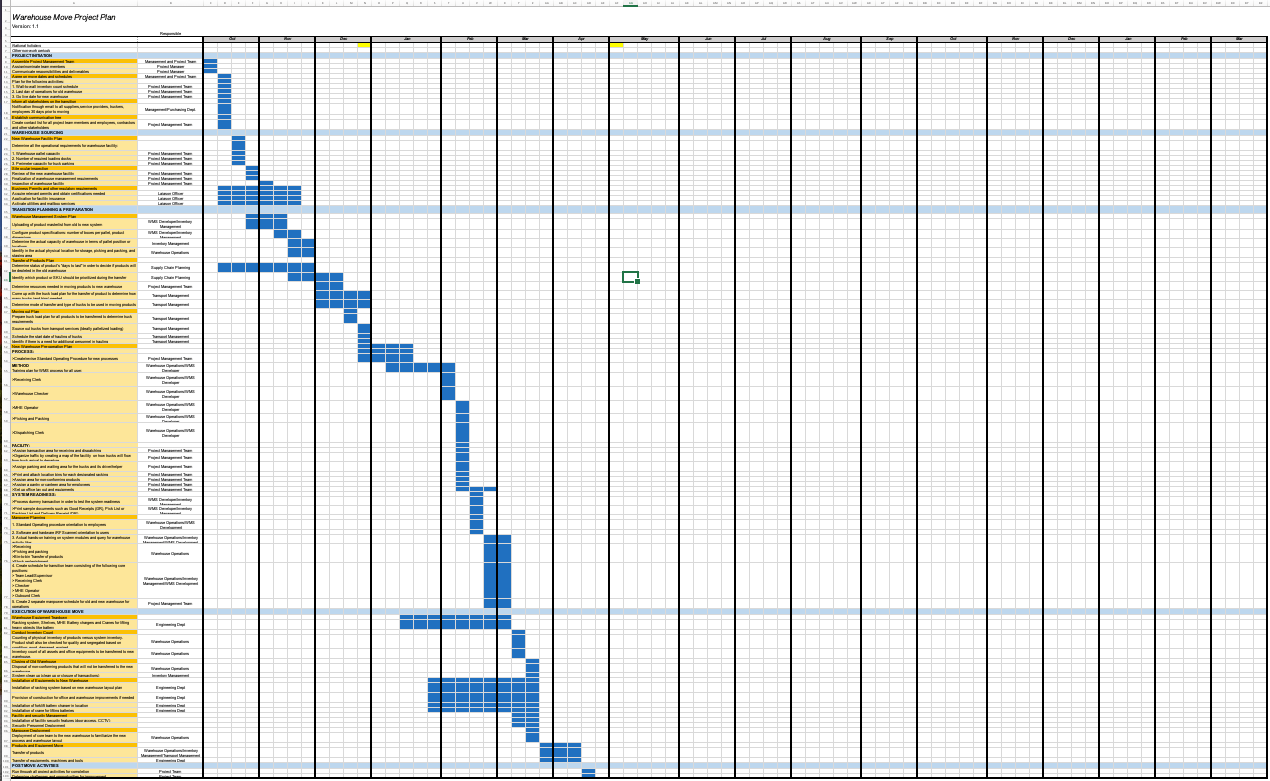

To help you prepare for the move and creating a rock-solid schedule, we have built a real-life warehouse move project plan that you can use as a template for building your own schedule.

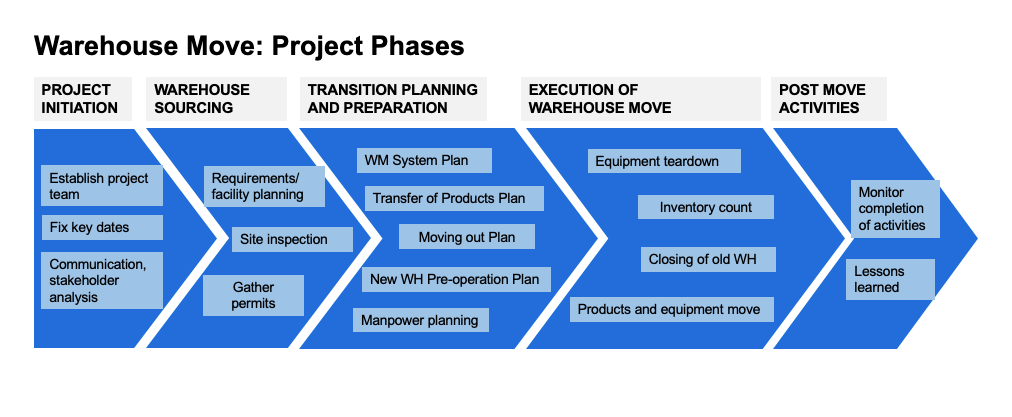

The playbook covers the scenario of a warehouse move from an existing warehouse into a new facility. The project plan is structured in the following phases and high-level activities:

Tasks are arranged in the following phases:

Here you can find some screenshots of the project plan:

The project plan provides a detailed and complete breakdown of the necessary tasks:

This is a generic project plan featuring a typical warehouse move into a new facility. It is meant as a foundation to speed up your planning process. You need to adapt the plan based on your specific scenario. In particular, take into account the following factors:

When I was looking for an expert to design the warehouse move project plan for us, I wanted to work with somebody with first-hand experience in managing several warehouse moves.

When I was looking for an expert to design the warehouse move project plan for us, I wanted to work with somebody with first-hand experience in managing several warehouse moves.

I was lucky to come across Ian Manlulu, a Logistics Operations specialist with over 12 years of experience in supply chain and warehouse management.

Ian has coordinated four large-scale warehouse transitions for major global brands involving millions of items and handling of sensitive products within the food category. Each warehouse move was completed successfully and within schedule and budget.

Ian also has tremendous knowledge of applying warehouse management systems in warehouse operations, and he has hands-on experience in the day-to-day management of large warehouses with capacities of up to 12’000 pallet positions.

If you are looking for help with planning your warehouse move, I am happy to connect you with Ian. Just drop a note.

As a Senior Project Manager I have managed large corporate projects for more than 10 years: SAP implementations, projects in logistics and engineering as well as finance projects (read my story). I started Tactial Project Manager in 2017 to share hands-on tips and practical tools to help you deliver high-stakes projects successfully. The sample project plans are created in cooperation with PMs having profound experience in the particular project category.

We are committed to provide you with useful and practical materials to help you in your work. If you feel the project plan is not what you were looking for, I am happy to return your investment within 30 days after your purchase. Just message me via the contact form.

We are committed to provide you with useful and practical materials to help you in your work. If you feel the project plan is not what you were looking for, I am happy to return your investment within 30 days after your purchase. Just message me via the contact form.

What scenario does the Warehouse Relocation Playbook cover?

The project plan covers a move from an existing warehouse into a new facility.

What format is the project plan provided in?

The project plan is provided as an editable Excel file. You can also import it to Google Sheets.

I have a question about the Playbook. How can I contact you?

Send me your question via the contact form.

What if I’m not happy with the project plan?

If you feel that the project plan is not what you were looking for, I’m happy to return your investment within 30 days after your purchase. Just send me a note via the contact form.

I have a question about the project plan. How can I reach you?

Send me your question via the following form:

We are currently working on new playbooks specifically for 3PL scenarios, including:

Go to the contact form page and let me know what you are planning to do so I can provide you with the most suitable playbook for your scenario.