Hello there!

Are you running an e-commerce business and trying to estimate future demand?

Would you like to know what helped me in my forecast planning?

If you’re nodding yes, then you already recognize the crucial role product planning plays, especially since it’s directly tied to your product fulfillment rate.

Effective product or sales forecasting can significantly boost a company’s growth. Conversely, getting it wrong can be a fast track to financial woes, even bankruptcy. This usually happens when poor demand forecasting leads to an excess of unsold inventory, causing substantial losses.

This article is designed to demystify the demand forecasting process, highlighting key factors you should consider. Remember, forecasting isn’t just about hazarding a guess on future product needs. It’s about crafting a strategic plan, one that encompasses not just what materials or products you need, but also where and when your customers need them.

While there are numerous techniques for forecasting product usage, we won’t delve into specifics here. Instead, my aim is to give you a clear understanding of how general demand forecasting works and guide you through the steps to effectively predict future demand for your e-commerce offerings.

What is demand forecasting?

Demand forecasting involves predicting future product demand by using forecasting models and using historical sales data. The process helps us anticipate customer needs in the coming months and years.

Before exploring the methods of forecasting, let’s familiarize ourselves with some key terms commonly used in this area:

- Issuance, Sales or Usage: These terms describe how goods or products are distributed to the end user. It represents the outward movement of items from the warehouse, leading to a decrease in stored inventory. It covers goods reaching customers, consumers, or the final stage of production.

- In-transit shipments: This term is used for products ordered from suppliers that are currently en route to the warehouse storage facility.

- Stock-On-Hand (or inventory): This refers to the physical products stored in the warehouse. It also refers to the physical stock available in the warehouse, ready to be dispatched to customers. If you have an inventory management system, this is where you can get your current stock levels.

What makes predicting future demand so challenging?

The challenge you face in predicting demand arises from various fluctuating factors that impact your forecasts both directly and indirectly. Here are some key elements to consider:

Reason 1: Shifting Customer Needs

Sudden changes in customer preferences and patterns in purchasing products can make product forecasting demand a difficult task. As an e-commerce business, you should closely monitor these trends and seasonal demand patterns to better prepare and adapt your forecast.

Reason 2: Shipment delays

This is a crucial issue you’ll often grapple with, as it directly affects product availability. Issues like port congestion, delayed shipping vessels, and other unforeseen events can lengthen the transit times of your shipments, leading to potential inventory shortages. To safeguard against this, it’s wise to plan for longer lead times, incorporating the average delays you might encounter, ensuring you always have enough inventory on hand.

Reason 3: Manufacturers’ Production Capacities

When placing orders, it’s important for you to be aware of your manufacturers’ production capabilities. This knowledge is key, especially when you experience a surge in demand, to confirm whether they can fulfill your orders. You should also consider identifying secondary manufacturers to step in if your primary suppliers can’t meet the required order volume.

Why is Good Demand Projection the Key To E-Commerce Success?

As you may have experienced yourself, e-commerce businesses can experience sudden growth in demand in a matter of months – or even weeks!

That’s why good demand projection is the key to keeping up with customer’s demands.

Some of the benefits that good demand can bring to your operation are:

Efficient Inventory Handling Inside Your Warehouse

Having too many products in your warehouse can lead to various operational challenges. Keeping inventory levels optimal is crucial for efficient and safe product handling. However, an excess of products can lead to overcrowding in your storage areas, raising the likelihood of mishandling, damage, and even product expiry.

Prevent Product Spoilage or Expiry

Perishable or food products have typically short shelf life therefore require careful planning in forecasting. Good planning for perishable or food products requires anticipating customer needs and at the same time not oversupplying inventory to prevent spoilage or expiry.

Creates Good Relationships With Suppliers

When demand for products suddenly spikes, it can strain your suppliers’ production capacity, while in contrast, there are periods of low demand. Good forecasting takes into account such fluctuations, aiming to balance product requirements across peak and off-peak seasons. A best practice is to include your suppliers in your demand planning process. This approach allows you to align with their capabilities and make necessary adjustments instead of placing last-minute orders in response to unexpected surges in demand.

Example: Performing Demand Forecasting For an E-Commerce Operator

Imagine an e-commerce company named “Scooby Snift Dawg Pet Supplie”s which offers 5 brands for dog food. It’s December 2023 and your task is to:

- Forecast the next remaining months from January to December of 2024 for each product using the historical sales from the past months.

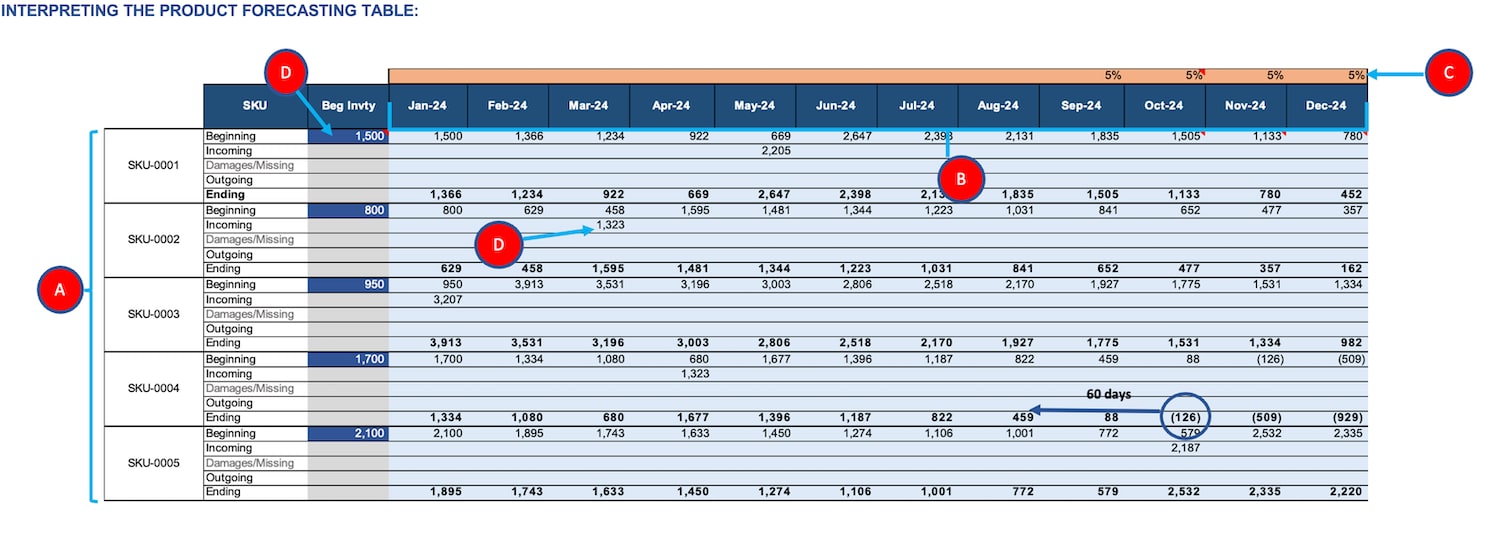

- Apply a 5% increase in product demand for the peak months of October, November and December. There are several variables to product forecasting, and two of those are seasonality and promotions for marketing. In the example, the last 3 quarters were identified as peak season (or high volume sales period). By comparing your previous month’s sales with the current, you get an idea of the percentage increase (or decrease) you need to apply.

- Create a product volume ordering schedule for each product according to suppliers.

Here is how you would handle this task:

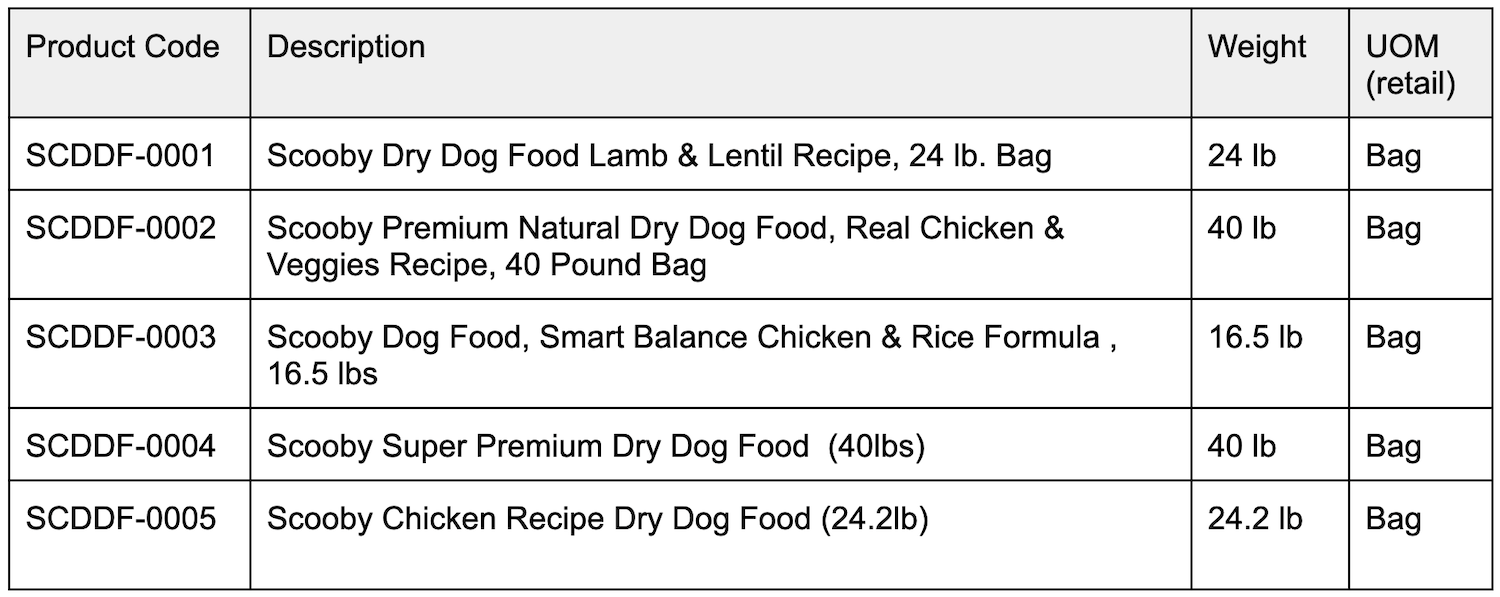

Step 1: Gather necessary product information

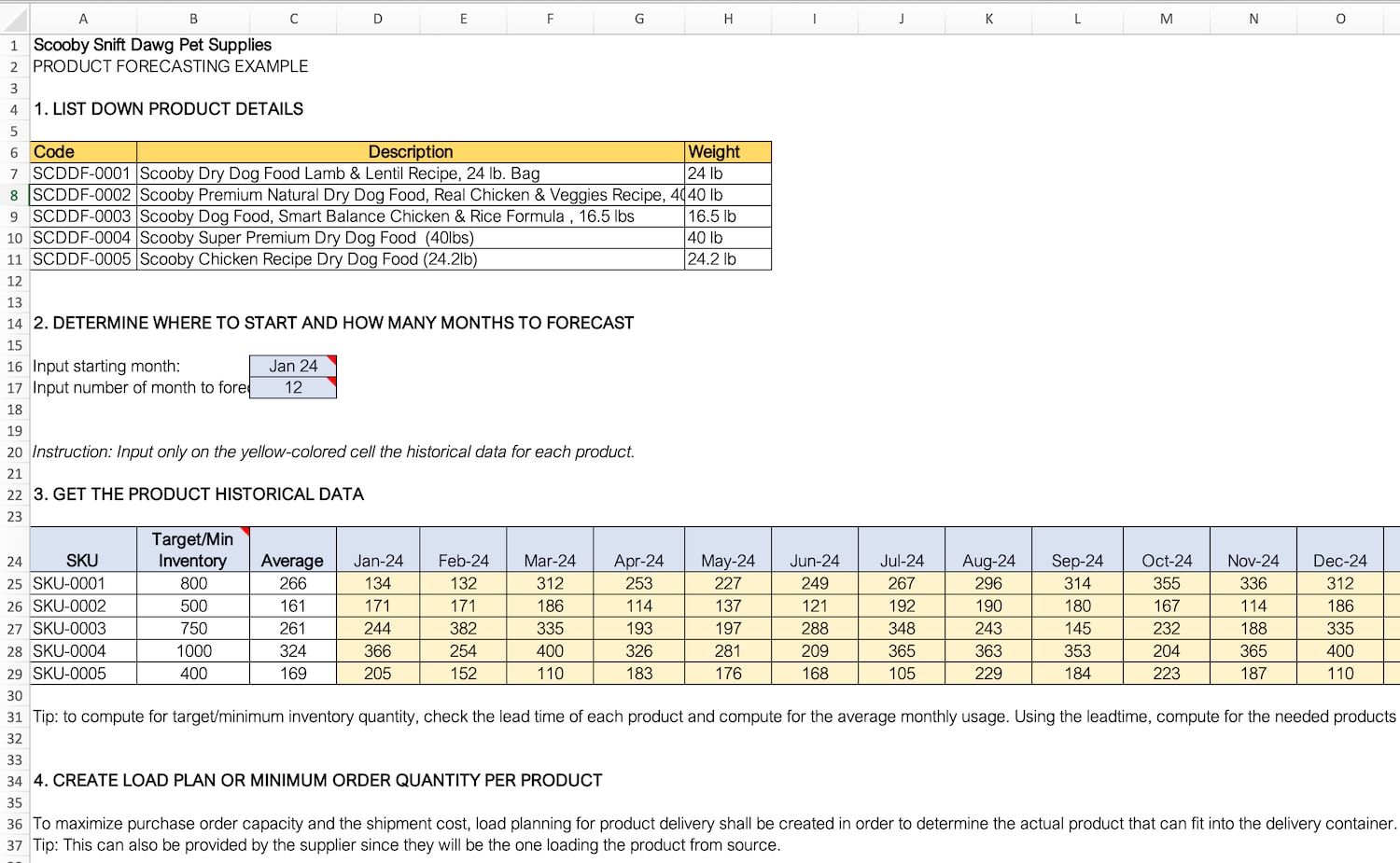

List down all necessary product information that is relevant for determining the product’s demand. It is critical to note that product UOM (or unit of measure) should be identified for both issuance to customer and ordering unit to supplier.

As an example, for product SCDDF-001, the retail unit of measure is 24 lbs equivalent to 1 bag. When ordering to suppliers, it is typically converted into tons to easily create a shipment plan for container delivery. Keep in mind that the order volume from suppliers may be broken down into multiple container loads based on its capacity.

To easily convert the units of measure for sales, I like to create an Excel table which looks like this:

Note: If for example, the supplier’s unit of measure is the same as the order quantity used by your customers, and equal to the handling quantity in your system, you can skip this process. This step is only necessary for products that are supplied or managed in a different unit of measure than the one customers buy them in.

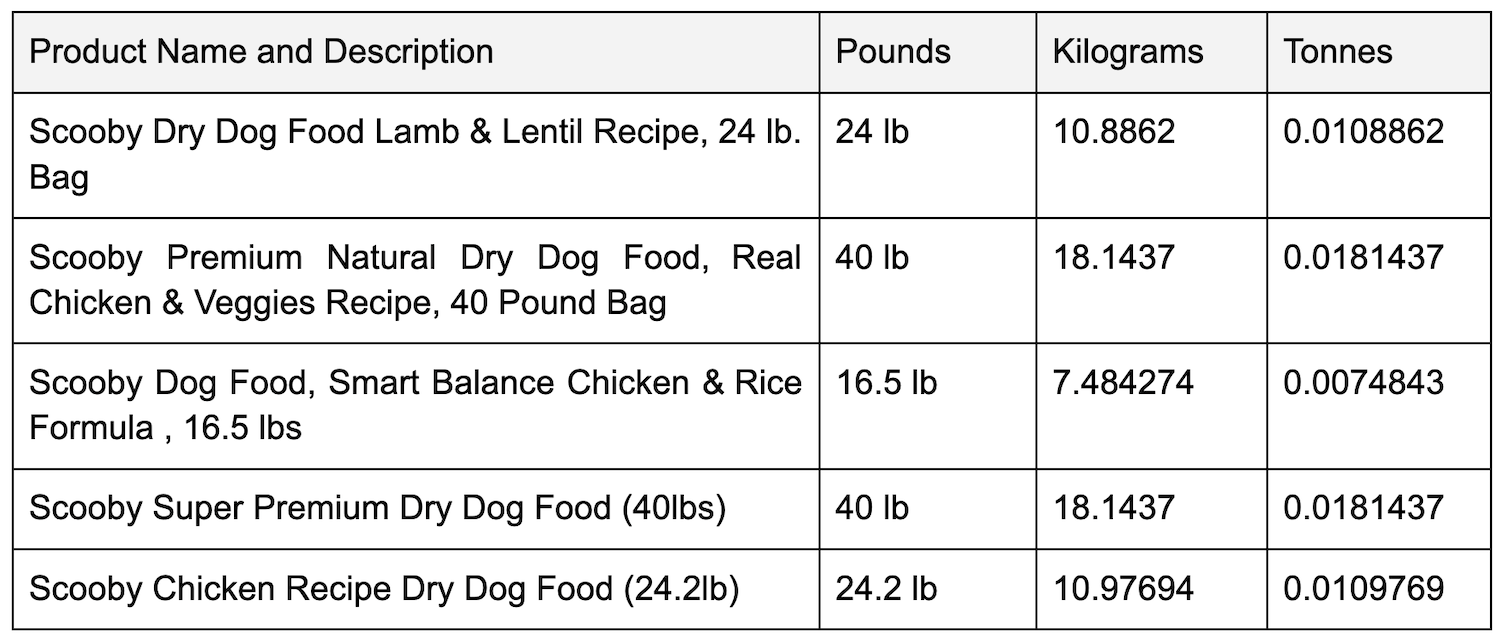

Step 2: Gather historical sales data

Get the historical data for each product from the past period. This would mean product sales, or usage, or issuance and or consumption from previous months. If you have an inventory management system, you can easily download the previous month or year. You may also want to take note of the trend and what month has the highest and lowest sales. This data is essential in forecasting products as this will be the basis of product replenishment.

How do you get the historical data? If you have system records of sales from platforms like Shopify or Amazon, you can simply download your sales per month. If you do not have any system, reach out to your sales department to get the numbers. To finalize, you may want to remove any unnecessary data that can be considered outliers so that your data set can be used to estimate future sales.

Example of historical data for the sample 5 products below:

The columns show the number of units sold via our dogfood e-commerce store.

Helpful links:

- Shopify Sales Analytics 101: Shopify’s sales reports give you insights about your store’s recent performance.

- Understanding Amazon’s Business Reports: This guide explains quite well the various parameters shown in Amazon’s sales reports.

- WooCommerce Reports: If you’re using WooCommerce, check out this guide to their sales reports

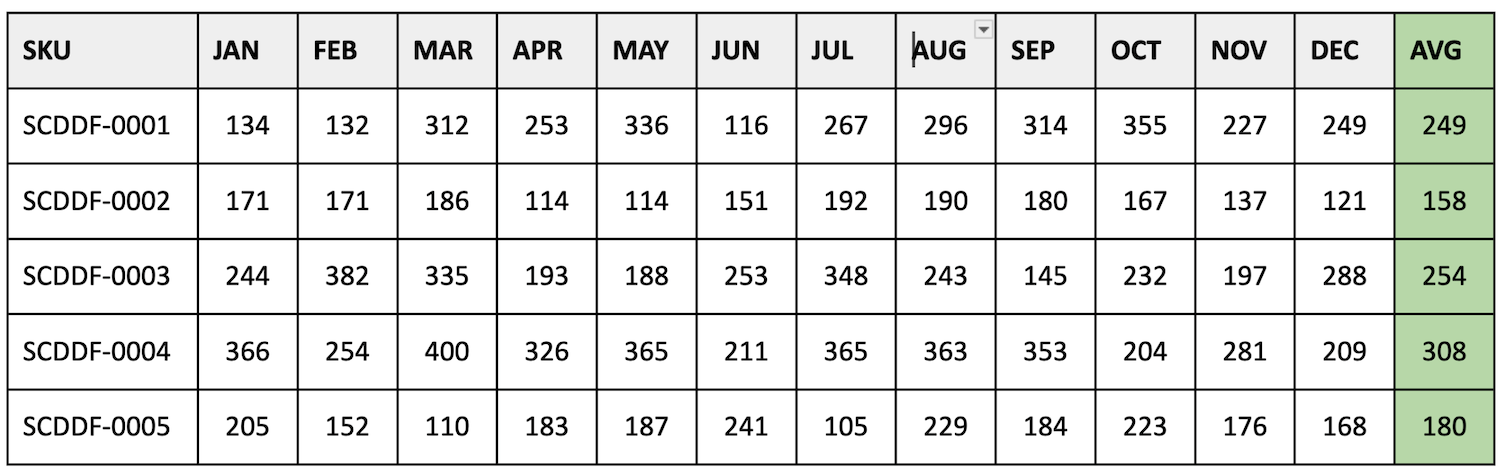

Step 3: Determine supplier lead times

Determine the average lead time of shipment of each product according to the supplier. When we talk about the average lead time of shipment, we refer to the average number of days it takes for the product to reach the destination warehouse, counting from the time of placing the purchase order.

Depending on the supplier, it is also important to keep in mind that some require a minimum order requirement (MOQ) for each product order which would also affect the order quantity in purchasing. Other suppliers will provide the manufacturing lead time, which is the time it takes for them to produce your order. Of course, we must consider the manufacturing lead time as well when computing the total lead time.

Example of determining lead time:

You submitted your purchase order of a product from the supplier by October 18, 2023, and on the same day, the order was acknowledged by the supplier. The supplier said that it would take them 7 days to manufacture your purchase order.

This is what it looks like:

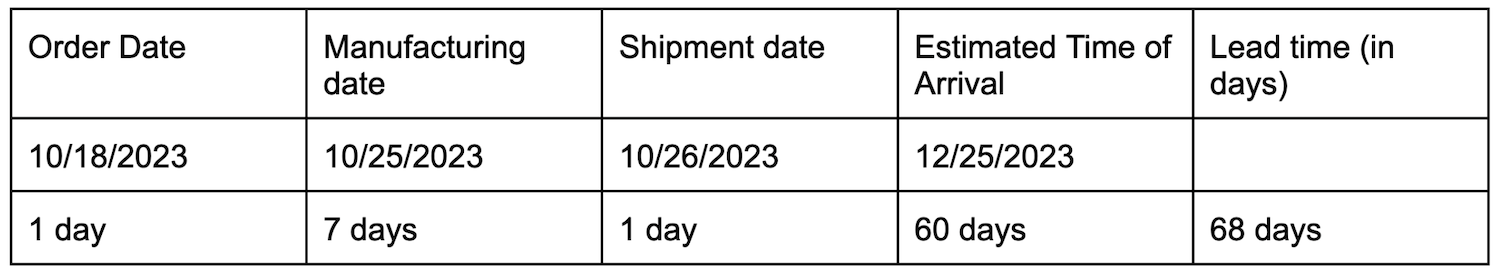

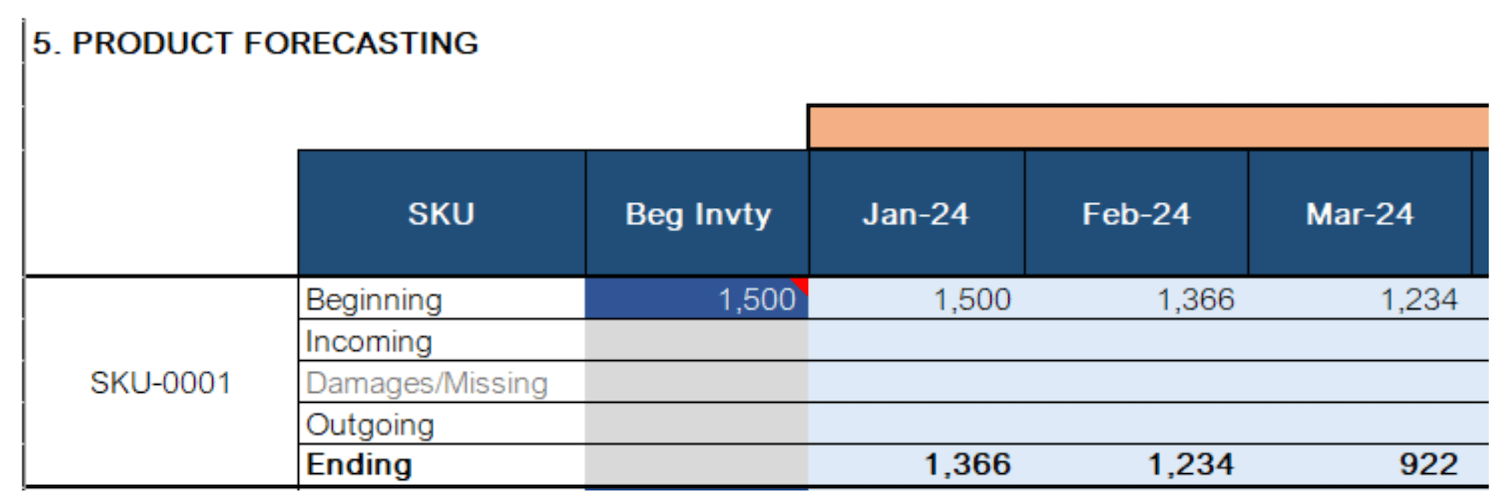

Step 4: Computing the product forecast in Excel

Based on the historical data from previous months, populate the data by using the average month of a given period. Add the beginning inventory, or the current inventory quantity available in the warehouse storage.

See illustration A:

Here’s an explanation of the rows:

- Beginning inventory:: This refers to the current inventory quantity available in the warehouse at the time you are making the forecast. This also refers to the stocks that are already received and ready to sell products.

- Average monthly usage: This is the average product usage of a product in a given period, taken from your historical sales data. Just review your past sales orders and calculate the average number of units sold.

- Incoming: This refers to the unloaded and received shipments from the supplier going into your warehouse/storage/fulfillment.

- Damage/Missing: These are the products that have already been received at the time of making the forecast, but due to mishandling inside the warehouse have been damaged or missing.

- Outgoing: These are other issuances or usage aside from the regular product that is going out of the warehouse. Examples of this are product samples to customers or other in-house departments like quality control, R&D (Research and Development) products, etc. that do not typically undergo the issuance process to customers.

- Ending: This is the quantity that is left when all the outgoing quantities are deducted.

The formula that connects all those numbers is:

(Beginning inventory + Incoming) Less: Average monthly usage, Damage/missing, Outgoing) = Ending Inventory

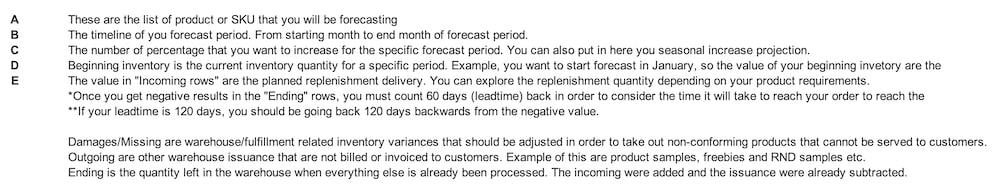

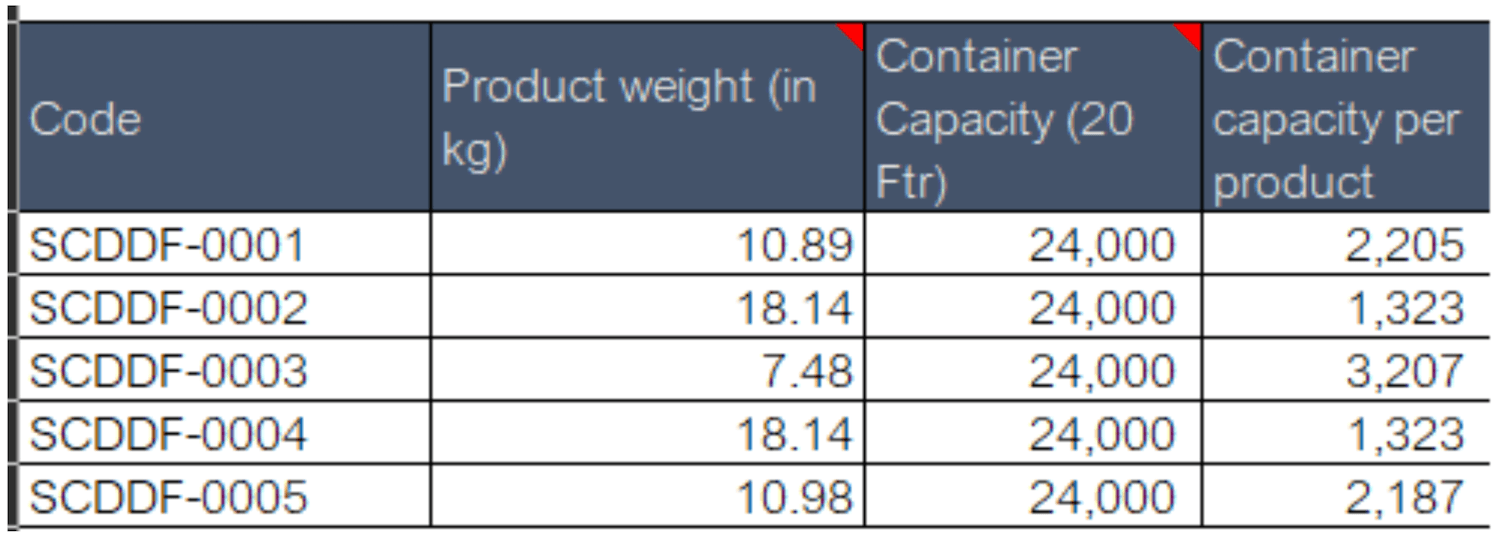

Step 5: Create a Truck or Container Load Plan

Determine how many delivery batches you will need in order to ship the total product requirements. It is important that you know the container van capacity in order to maximize the freight cost for each shipment. Ideally, delivery container vans should be maximized in terms of metric tons capacity. If in case you have below minimum order quantity, you can maximize the container by including other product orders in the load plan.

Order to suppliers should follow the delivery container capacity. For example, a 20-footer container van has a capacity of 25 tons. To use this, you will need 260 bags of the product SCDDF-0001 to be able to fully maximize it as a full container load or FCL.

Tip: In order to maximize the delivery or shipment cost, it is important to ensure that the truck or container is utilized to its allowed capacity, that is why it is critical to perform load planning. You can ask your supplier about this data.

Illustration B:

Container truck load planning

Step 6: Determine the quantity of your purchase order

Once you have computed the quantity of products to be ordered, prepare the purchase order for each supplier. Organize your forecast by supplier, as this will be essential in creating the PO quantities. Organizing your orders according to product and supplier will help you ensure that no purchase order is sent out to the wrong supplier.

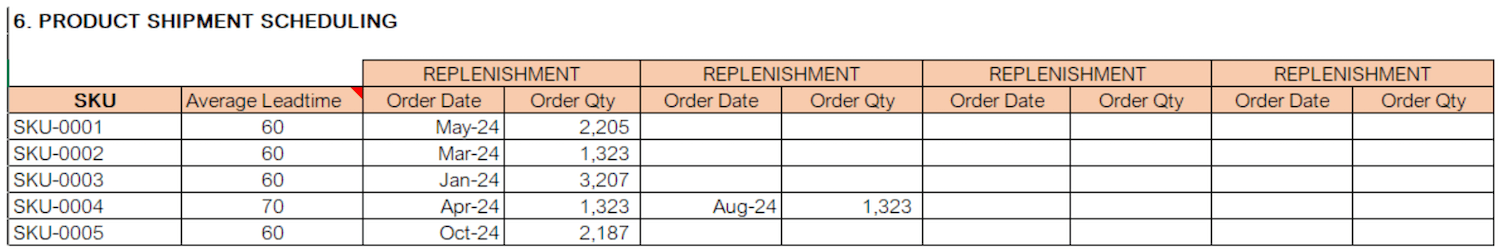

Don’t Forget To Set Up An Inventory Replenishment Process

Effective inventory management is not just focused on product demand forecasting. It’s also about how to sustain the desired level of inventory that can fulfill customer’s orders and manage incoming shipments from suppliers.

Managing your purchases from suppliers by taking into consideration the lead time on when they will arrive at your warehouse or distribution center is a process called inventory replenishment. This is replenishing your inventory level of new stocks from suppliers for the product inventory to last until the next delivery from your suppliers.

Product or inventory replenishment can be done by creating a scheduled product replenishment or delivery that is based on your demand forecast. The benefit of creating a delivery schedule is to plan ahead on when you will do your purchase having in mind the production lead time and shipment lead time. It can also give you an overall view of what to expect in the period you are forecasting.

It might help your supplier or manufacturer to plan ahead too of their production schedule by communicating to them your future needs, therefore, creating a good relationship with them.

Illustration C:

(Inventory replenishment table)

My Demand Forecasting Template - Download It Here!

You can download my forecasting template here. It’s the same sheet that I have been using for this example. The Excel sheet comes with detailed, step-by-step instructions, explaining what goes into each column and row. Unlike other forecasting sheets, this one is really straightforward to use, enabling you to quickly assemble a sales forecast for your e-commerce store. In the same file you’ll find the calculated example from this article, so you can easily replicate the steps!

Got A Question? Need Some Help?

Have a question about this article? Need some assistance with this topic (or anything else)? Send it in and I’ll get back to you personally.

Key Takeaways

When forecasting customer demand as an e-commerce business, remember that your approach should vary based on your product type and overall market factors. While perfect forecasting is not always possible, you can enhance your accuracy by consistently reviewing and researching market trends and customer buying habits. This insight allows you to respond swiftly and adapt to future market shifts.

Building a strong relationship with your suppliers is crucial. It helps ensure timely order fulfillment and the production of high-quality products in large volumes. Be mindful of placing large, sudden orders, as these can overwhelm your supplier’s capacity, leading to unfulfilled orders. Knowing your manufacturer’s limits and having a reliable secondary manufacturer is essential for maintaining consistent product quality.

Ultimately, your goal is to satisfy customer orders while maintaining an adequate inventory level. Strive for a balance: avoid excessive stock, yet have enough to last until the next replenishment. This balance is key to preventing stock shortages and effectively managing your inventory through forecasting.

That’s it! I hope you found my elaborations on demand planning helpful. I wish you much success with your e-commerce business!

Author

-

Ian, an Industrial Engineering major, brings over a decade of Supply Chain Management expertise to the table. His journey spans 12 years across various sectors, particularly in multinational FMCG companies where he managed extensive warehouse operations. A pro in inventory, order, and transportation management, Ian is now channeling his rich experience into guiding a construction company's operations where he handles forecasting product needs for multiple warehouses across several countries.