Welcome!

I know you are here because you are in search of something that can help you achieve your desired performance in your inventory management, and you have come to the right place.

I understand the frustration of managing inventory using manual monitoring because I have experienced the same. To save you time from trying things and to save you from unnecessary inventory costs, I have created this article to help you understand each process and explain to you based on experience what are the things that worked out. I hope you will find this relevant and helpful.

In this article, we will talk about your roadmap for managing your inventory management implementation. Having good processes and guidelines for managing inventory is the key to growing and scaling your business. With the right process and system to support the supply chain, managing your inventory is critical to the success and failure of your business.

My name is Ian Manlulu, and I have been in warehousing and logistics operations for more than a decade. I am here to help you by giving you step by step process for migrating to an inventory management system so you’ll have a smooth transition.

We’ve all struggled with manual inventory management

Managing inventory comes in different ways. Most start-ups and small businesses typically use spreadsheets for monitoring and managing their inventory. Using spreadsheets is a good tool for monitoring your product inventory, although it requires consistency in updating the file and accuracy on the part of the process owner to have a credible report.

If you are managing your inventory manually using spreadsheets, you are probably experiencing these problems I too have encountered:

- Limitations on spreadsheet capacity: Admit it, the more products you are keeping, the more likely it is for you to have a large working file when it comes to monitoring your daily transactions. Since spreadsheets have limitations, you are likely to keep multiple files. If you have experienced reaching the spreadsheet capacity, you might want to consider getting your inventory management system software.

- Lagging of spreadsheet files due to large volume of formulas: Along with the limitations of spreadsheets also comes the downtime of lagging files due to the large volume of formulas in the file.

- Multiple copies of the original working file: Have you lost track of the original file you are working on and cannot tell the difference between the original file and the copy? Or you can’t tell which one is the most updated and which one is not? Do you have multiple copies of your inventory monitoring file name in your download folder? Manual monitoring of inventory using spreadsheets comes with these downsides.

- Your working file can be edited by anyone: Although spreadsheets can be locked by a password, sometimes they can be altered unintentionally by the user. If there are important formulas that are unintentionally altered, the file and the credibility of data would be affected.

- Manual spreadsheets take time to update: Have you experienced badly needing an inventory report and you get the response “I need time to update the monitoring”? Manual spreadsheets take time to update and therefore having the possibility of getting the reports in real-time is difficult.

- Unreliable data: Have you ever committed to your customer that you have available products to sell and found out that the products have been sold out because you just relied on the inventory report from an undated day?

Aside from the limitations of spreadsheets in manual inventory monitoring, there are typical challenges because of using manual inventory management. They are as follows:

- Delays in planning/forecasting: I remember before when I was managing a warehouse that used manual inventory monitoring, the inter-warehouse transfer plans relied solely on the availability of data. If the manual spreadsheet takes time to update, it is possible that there may be waiting time in the execution of product movements.

- Possibility of unfulfilled orders: The planning and forecasting department shall have real-time visibility of each product inventory to ensure that physical inventory in the warehouse shall meet the current customer’s order. Strong monitoring of inventory performance along with effective demand forecasting can minimize or may even eliminate out-of-stock of products, which has a huge impact on customer satisfaction.

When's the right time to switch to system-supported inventory management?

One of the most critical decisions of every growing company is to decide when to switch from manual inventory monitoring to an inventory management system. Below are the guidelines that you may consider in switching to automated inventory management:

- When errors related to inventory performance are costly: Every product you purchased has a corresponding cost on your part. So when errors in the inventory lead to inefficiency, most probably it has a corresponding impact on your financial performance. When gross errors are committed like overstocking leading to spoilage or expiry of products, it can tremendously impact your company’s profitability. If you incur a monthly loss by using a manual inventory spreadsheet, it is time to explore other options and switch to an inventory management system to automate your inventory needs.

- When updating your inventory spreadsheet takes up too much time: Usually, manual spreadsheets take time to update which is only achieved by inputting transactions into your monitoring. If you need the information in real-time, you might want to consider switching to an inventory management system that offers real-time reports, and trends, and is able to capture sensitive data like order fulfillment rate, product returns, what and when to reorder products and other performance indicators.

- When you need critical information available in real-time: Real-time information from your inventory performance is one of the critical feats you need to make sound business decisions. So, if you are stuck with manual spreadsheet reports, you are probably missing out or not making the best out of technology. Real-time data lets you monitor your performance in real-time, thus helping you make quick actions that your business needs to cope with or to adjust requirements.

How an Inventory Management System will benefit your operation

On the contrary, a well-executed inventory management system has many benefits to the process owner and also to the stakeholder within the organization. Below are the lists:

Impact on Warehouse and Logistics operations

Inventory management is the heart of the warehouse and logistics operations, an inventory management performing well could mean maximum efficiency in the warehouse operations.

These will result in:

- Increased productivity: A well-executed inventory management system would mean that the warehouse personnel would know how much product is in storage and where to find the product up until the last piece because every product quantity is accounted for. In preparing orders, this is essential because the order picker can go directly to the location, therefore, it can shorten the processing time in picking and packing instead of looking and searching for products that they need in fulfilling customer orders.

- Reduction or elimination of unserved products: A healthy inventory management system will benefit the warehouse operations by having a good accounting of products inside the warehouse. In warehouse operations, it is critical that the process owners are aware of the product’s availability as they are the ones picking and fulfilling customer orders physically. Inventory management systems can provide real-time inventory balance that can be the reference of the process owner in product order allocation. A reliable and real-time inventory management system can be a great tool in achieving one hundred percent fulfillment of customers’ orders.

Impact on Production Planning

- Accuracy in inventory reports is the basis of planning or forecasting of products, therefore well-executed inventory management shall result in achieving the expected computed forecast.

- Inconsistency in the inventory reports in terms of quantity would affect the reliability of forecast and therefore pose a risk of product out of stocks.

Financial impact

- Inventory management is directly correlated to the financial aspect of any business. As the inventory quantity of products increases, so does the cost of product handling and storage. Inventory should be computed at the desired level to be able to cater to customer orders and at the same time not overstock.

- Also, inaccuracy in the inventory leading to variance such as lacking, over, or short-over (switching of similar appearance product in picking) may lead to financial loss.

Impact on Customer Service

- Well-executed inventory management will result in accurate inventory that will also lead to the fulfillment of customers’ orders. This is the main purpose of any business, to fulfill the customers’ orders and make them come back for a purchase.

- One of the measures of a well-performing inventory is that you can fulfill 100% of your customer’s orders. This increases customer satisfaction and minimizes your customer’s complaints related to product availability and fulfillment.

Key criteria for selecting an inventory management system

Depending on the need of your organization and the complexity of your warehouse operations or distribution center, the criteria for selecting inventory management systems are as follows:

System Capability

There are plenty of systems to choose from when it comes to inventory management systems, and it is best to know each of their capabilities and features. Ideally, these are the things to look for in choosing a system: one that can help you in demand planning, prompt you when you must reorder or replenish inventory, help you with organizing and reminding you of supplier obligations on payment etc.

Given that the system will be tracking inventory, it is important to note that the synching of data and transactions should also be real-time in order to get accurate information from the system.

Process Customizability

The system’s ability to be customized for your unique needs and requirements should also be on your list in considering your inventory management system. These features enable the user to tweak the inventory management process according to the essential process to maximize the use of the system for each transaction.

A specific example of customization is the inventory allocation strategy: Depending on your product and industry, you may include shelf life in the product maintenance detail in order for the system to prioritize lower shelf life in goods issuance for customer orders. The typical inventory management strategy or method in managing food products is “First In, First Out” (FIFO). You can customize this inventory strategy based on your product allocation method in order for the system to prioritize products during order allocation.

System integration features

This feature should be one of the most essential criteria in selecting an inventory management system. System integration with other project management tools or reporting tools is nowadays part of monitoring daily operations. With this feature, it can give the user quick access to the data in real-time and can be used to make relevant business decisions.

An example would be linking your e-commerce platform to your inventory management system. This integration which is commonly achieved using system APIs (Application Programming Interfaces) will help you check your inventory level and at the same time you receive sales orders.

Another example of this is the ERP system integrated to your inventory management system. Enterprise Resource Planning integrated to your inventory management system can help you plan the demand and forecast for your low-quantity products so that you can replenish on time. This tool can also be used in managing purchases from suppliers as well as monitoring the financial status of your transactions like billing, accounts receivable and payments.

Dashboards or reports that it can produce

Inventory forecasting, product volume trends, seasonality of products, and individual product performance are just some of the reports a good inventory management solution is able to provide.

After-sales support

Companies should not be left to their own devices after the implementation of the system is completed. That is why it is important to request competent after-sales support to ensure that future problems are properly addressed.

System maintenance and updates

Continuous update of the system is a sure sign of performance improvement. The vendor should provide regular updates to address bugs and other troubleshooting errors that can affect the overall performance of the system.

Identifying your Inventory Management System requirements

To help you narrow down your requirements, I have listed down points you can consider in selecting the right inventory management system for your company. These points will help you have a clearer picture to communicate to your vendor in laying down your requirements.

- Product master list complexity: Identify how many materials or products you will be maintaining in the system. Along with this come also your product variants, different colors, sizes or other variants.

- How many distribution centers or channels will you be operating? Operating multiple channels of distribution is a complex process when it comes to monitoring and maintaining the overall inventory performance of each channel. It is important to keep in mind how many distribution channels you will have or are planning to have so that those will also be covered when selecting your system.

- What purpose will your inventory management systems be used for? There are plenty of inventory management systems available in the market, and each has a particular purpose. Although both Inventory Management Systems and Warehouse Management Systems are used to manage inventory, the two are separate systems with different functionality.

- Inventory Management: This type of system is typically used to manage the overall inventory performance along with the accounting and financial side of your business.

- Warehouse Management System: A system that is used to manage your internal warehouse transactions to track the process in real time.

How to know your inventory management is performing

In my experience in supply chain for more than a decade, there are some indicators I look for to know that inventory is performing well. There are many possible techniques on how to know your inventory management is performing, the simplest indicator that you have a healthy inventory management are:

- Minimal or no out-of-stock of products: Frequent out-of-stock scenario is an indication that you have deeper inventory management issues. If your fulfillment provider or warehouse operations frequently report out-of-stock, it is either a result of poor planning or inaccurate inventory recording and sometimes of both. So, if there are minimal or no out-of-stock scenarios, chances are you have good inventory management.

- System quantity and physical quantity of inventory are accurate: When you account for products through daily cycle counting or inventory counting, the more the physical quantity matches the system quantity, the more accurate your inventory record will be. This is also an indication of inventory management performing well as this means that all transactions are accounted for properly and transacted accurately.

- All products are properly accounted for: An inventory management system is your tool to monitor all the transactions within your supply chain operations, from PO (purchase order), goods receipt, warehouse storage movements, picking and packing to delivery receipt. All physical transactions and movements shall also have corresponding system transactions to maintain the credibility of the inventory record.

Now that you have an idea of how the inventory management system works and how to choose a system based on your company’s needs and requirements, but do not have the experience of not yet experienced migrating from a manual to a system-managed inventory, do not worry, let our expert help you with this detailed migration plan.

Migrating from manual inventory to an inventory management system

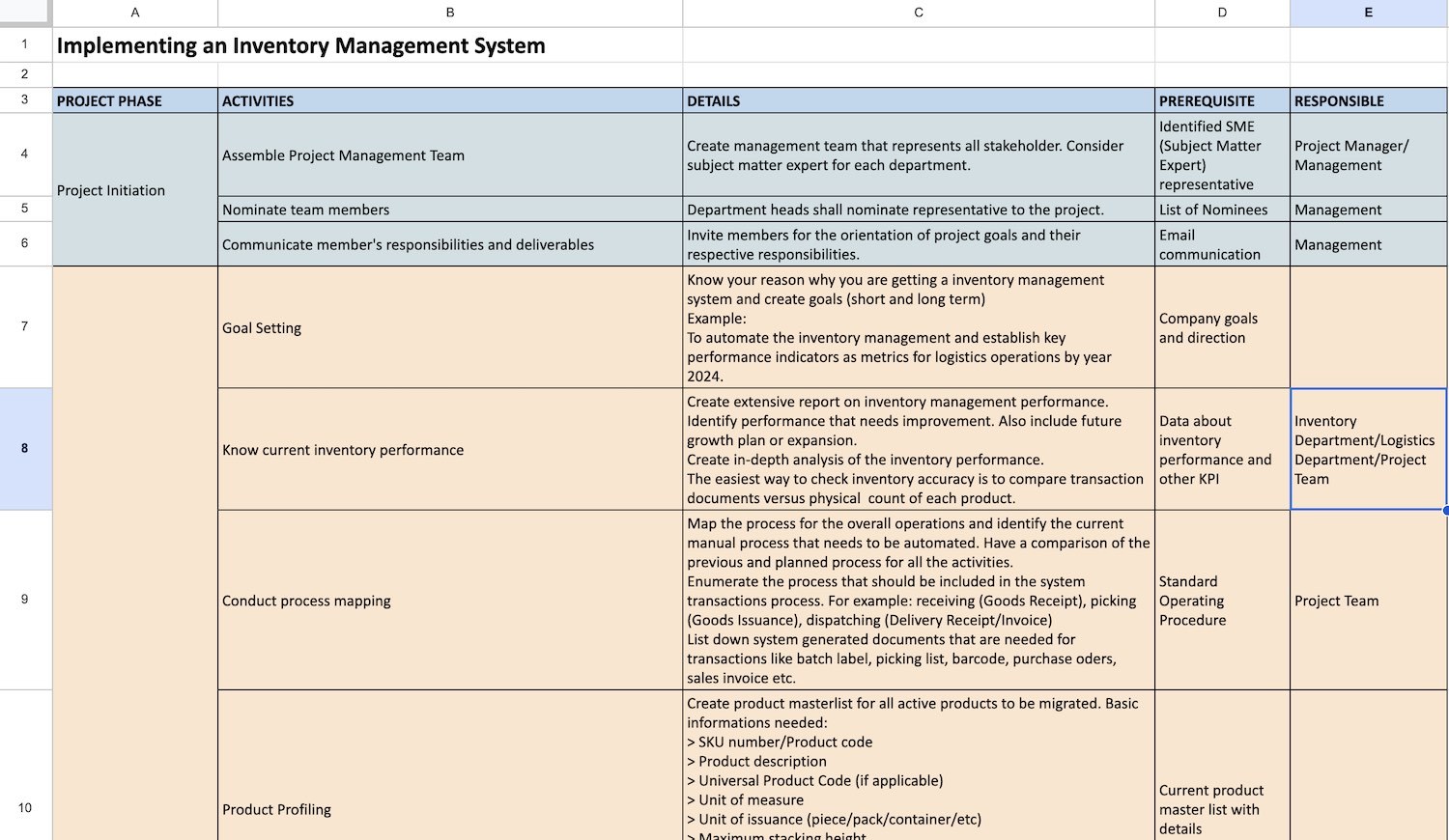

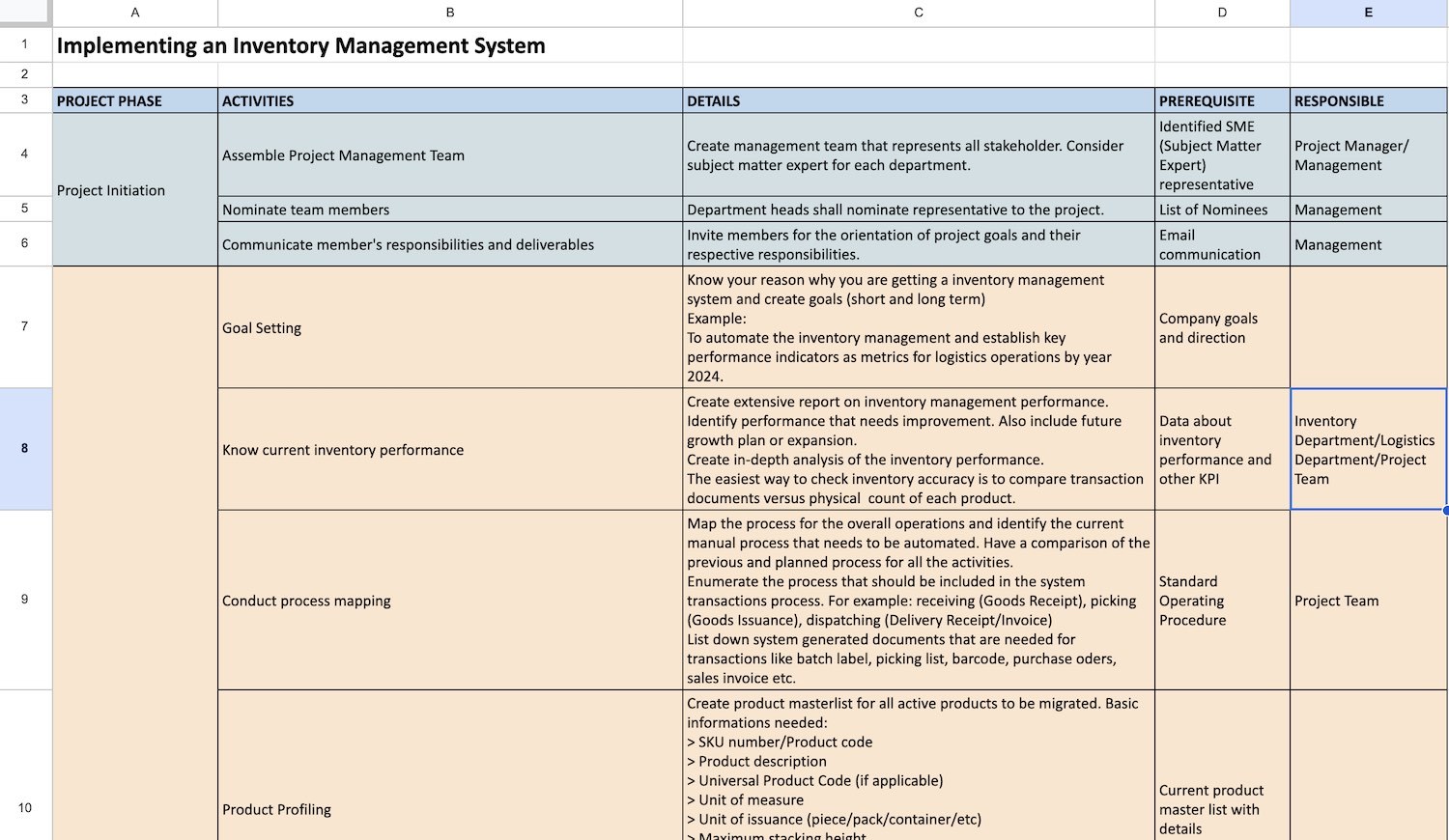

In migrating your inventory management system from manual, you need a detailed project plan to ensure successful and smooth implementation of system migration without delays in your operations. I have created a detailed project plan template that is based on my experience in the past in migrating to an inventory management system.

It is important to identify first what kind of inventory management system your operations need to come up with the right system to support your overall supply chain operations.

For large-scale warehouses or storage with plenty of products to manage, it is recommended to use a warehouse management system (WMS) in managing your inventory. Complex operations need more detailed inventory tracking than an inventory management system can offer.

A WMS can help you manage your transactions inside your warehouse operations from receiving, put-away of products, storing of products to specific locations, replenishment, bin-to-bin transfer, inventory counting or daily cycle count, picking and packing to delivery. It is basically a system that can guide you on the warehouse activities like where to locate and find your product with the designated bin location.

Check out our playbook for implementing a WMS!

THIS playbook walks you through the steps for introducing an inventory management system for your company:

Establishing suitable key performance indicators (KPIs)

Key performance indicators are your barometer for knowing the current state of your business. In a practical illustration, they give you the green light if the performance is hitting targets and a red light if the performance is below the target.

Below are examples of key performance indicators that are typically used to monitor inventory performance:

- Product Aging: This is a measure of how long products stay in your warehouse and is typically measured in the number of days. The longer you hold your inventory, the more cost you will incur.

- Inventory Record Accuracy: This metric measures your product accuracy based on the physical count and your system inventory count. Ideally, the physical quantity should match your system inventory quantity for each product. Differences between physical and system quantity shall mean variance, which entails cost.

- Inventory Managed: measures the overall quantity accuracy for each product.

- Warehouse Management System: measures product, location, handling unit, quantity accuracy as parameters in measuring the accuracy of physical products versus system balance.

- Order fulfillment rate: Total number of orders received versus the total number of orders served.

- Inventory Turnover Ratio: It is measured by a ratio that can be calculated by computing the cost of goods sold divided by the average inventory. If the result has a higher ratio, it simply means that your products are frequently sold and may result in frequent replenishment. On the other hand, lower ratios mean that you are holding your inventory longer for a time period.

In my previous experience in Supply Chain we measured what we call, Inventory Record Accuracy. Like what I have listed above, this is a technique that measures the accuracy of products based on different parameters.

Normally, companies measure product, expiry date or consume-until date (if it has one) and quantity. For warehouse management systems, they have a more complex way of measuring inventory accuracy since the location of products and their unique code in the system are also part of their accuracy metrics.

These are essential barometers as we call them the “vital signs” of our logistics operations. It is important these metrics are monitored and measured as they are directly related to the financial performance of your business. Other signs of an unhealthy inventory management system are the incidences of variances like short/over quantity, product damages inside the warehouse and expired products.

Summary: How to safely move to an inventory management system

To ensure smooth migration to an inventory management system, companies should focus primarily on picking the right inventory management system that fits their current and future needs. Remember also that by implementing an inventory management system your process should be simplified and centralized to the system you are using when it comes to transacting each process.

If you can find an inventory management system that integrates your product accounting, track inventory movements, supplier payment and other billing obligations into one system monitoring will be a great tool in monitoring the overall profitability of your business. And lastly, it is equally important that when you have decided to implement an automated system like an inventory management system, your physical inventory should match your system inventory quantity.

It is crucial that the initial balance uploaded to the new system should have 100% accuracy to ensure that all orders from the system will have corresponding physical product to ensure fulfillment.

An inventory management system is just a tool to help you in achieving your inventory performance target, it should also be paired with sound inventory guidelines, good forecasting techniques and policy that will ensure standard processes are well executed and followed by the process owner.

THIS playbook walks you through the steps for introducing an inventory management system for your company:

Author

-

Ian, an Industrial Engineering major, brings over a decade of Supply Chain Management expertise to the table. His journey spans 12 years across various sectors, particularly in multinational FMCG companies where he managed extensive warehouse operations. A pro in inventory, order, and transportation management, Ian is now channeling his rich experience into guiding a construction company's operations where he handles forecasting product needs for multiple warehouses across several countries.